FarmPays Nigeria: Agricultural inputs, fast delivery, expert consultation

.

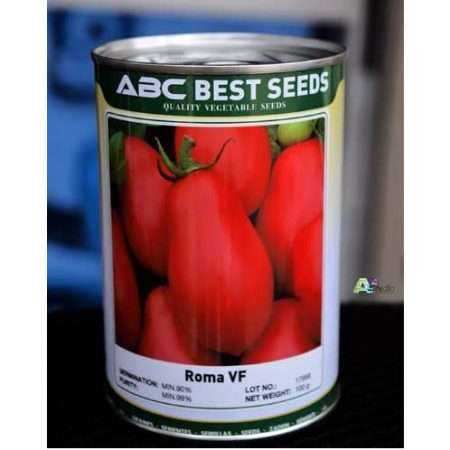

At Farmpays, we understand that farmers need access to high-quality agricultural inputs at competitive prices, as well as timely delivery and expert advice. That’s why we offer a wide range of agricultural inputs, including seeds, fertilizers, pesticides, and herbicides, at competitive prices, with fast delivery and free consultation from our team of experienced agronomists.

Whether you’re a smallholder farmer or a large commercial farm, we have the agricultural inputs you need to succeed. We also offer a variety of payment options to make it easy for you to get the inputs you need, when you need them.

Order your agricultural inputs from Farmpays today and experience the difference!