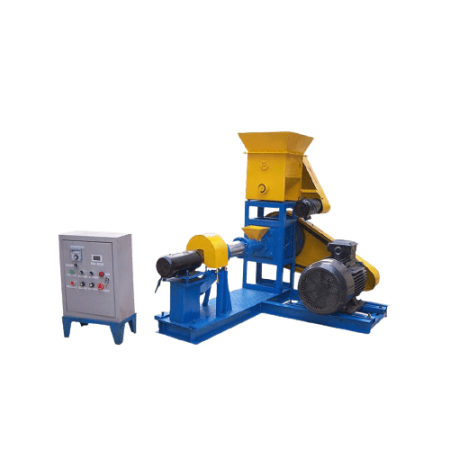

Medium Capacity Feed Pelletizer

₦1,396,750.00

13 people are viewing this product right now

🔥 8 items sold in last 3 hours

A medium capacity feed pelletizer is a versatile machine that can be used to produce high-quality animal feed pellets. It is a cost-effective way to improve the digestibility and nutrient absorption of feed, which can lead to better animal health and performance.

Benefits:

There are many benefits to using a medium capacity feed pelletizer, including:

- Improved feed quality: Pelletized feed is more digestible and nutritious than loose feed, which can lead to better animal health and performance.

- Reduced dust: Pelletizing helps to reduce dust, which can improve air quality and reduce the risk of respiratory problems in animals.

- Improved flowability: Pelletized feed flows more easily than loose feed, which makes it easier to handle and store.

- Increased shelf life: Pelletized feed has a longer shelf life than loose feed, which can help to reduce waste.

- Cost-effectiveness: Pelletizing can be a cost-effective way to produce animal feed, especially when compared to other methods, such as chopping or grinding.

Buy more save more!

Buy from 5 to ∞ items and get 5% OFF

on each productA medium capacity feed pelletizer is a machine that is used to grind and compress feed materials into small, uniform pellets. The machine consists of a hopper, a grinder, a compression chamber, and a die. The feed materials are fed into the hopper and then ground into a fine powder by the grinder. The powder is then compressed into pellets in the compression chamber. The pellets are then discharged from the die.

The size and capacity of a medium capacity feed pelletizer can vary depending on the needs of the user. Some machines can produce up to 1 ton of pellets per hour. Medium capacity feed pelletizers are typically used by small to medium-sized farms and feed mills.

Feed Pelleting Machine

The Medium Capacity Feed Pelletizer (level kick the bucket pelletizer) is utilized for changing over feed fixings that are in squash structure into dry pellets bringing about solid, smooth pellets that are useful for taking care of domesticated animals. Hence, it transforms pound takes care of into pellets without adding water, creating different sizes of pellets – 2mm for Juveniles, 4mm for post-adolescents just as 6mm and 8mm. The size of pellets you decide to deliver relies upon the age and size of the fish.

Provisions of Medium Capacity Feed Pelletizer

The Flat Die Pelletizer is particularly helpful for limited scope creation as it is lightweight, has a straightforward design, burns-through low force, and is entirely reasonable.

The key parts are the kick the bucket and roller which are made of top notch amalgam material and is very much treated with hotness to guarantee the sturdiness of the machine.

The machine is extremely simple to work, and it delivers exceptionally low commotion.

The Flat Die Pelletizer comes in different limits relying upon your expected degree of creation.

Benefits of utilizing the item

Transmission type: Gear transmission.

Can be utilized for birds, chicken, sheep, dairy cattle, bunny and other poultry and creatures.

Straightforward design, simple to work, little volume size, and low commotion.

Unrefined substance: Maize, wheat grain, soybean dinner, soybean, grass powder, broken straw and so forth

The feed can be developed underway which can further develop the ingestion effectiveness of supplements and kill the parasites of Common pathogenic microorganisms.

With the pellet creation under the strain of the actual machine, the starch in the feed can be developed to a degree and produce a solid smell.

Hard surface feed adjusts to the attributes of the pig, cow, and sheep and further develop the feed tastefulness, and simple of eating.

Level pass on and roller made of high-compound wear-safe materials, contrasted and the ordinary machine, our machines will work for longer help life.

Frequently Asked Questions (FAQs) About Medium Capacity Feed Pellet Machines

What is a medium capacity feed pelletizer?

A medium capacity feed pelletizer is a machine used to transform loose feed materials like grains and powders into compact, uniform pellets. These pellets are easier for animals to eat and digest.

How does a medium capacity feed pelletizer work?

The machine typically has four main parts:

- Hopper: This is where the loose feed materials are loaded.

- Grinder: This section grinds the feed materials into a fine powder.

- Compression chamber: Here, the powdered feed is compressed into pellets using rollers and a die.

- Die: This determines the size and shape of the final pellets.

What are the benefits of using a medium capacity feed pelletizer?

- Improved feed efficiency: Pellets are easier for animals to digest, leading to less waste and potentially increased growth rates.

- Reduced dust: Pelleting helps minimize dust in feed, improving air quality and potentially reducing respiratory problems in animals.

- Easier handling and storage: Pellets are easier to transport and store compared to loose feed.

- Customizable feed sizes: You can adjust the die size to create pellets suitable for different animal ages and sizes.

- Potential for killing bacteria: The pelleting process under pressure may help eliminate some common bacteria in the feed.

- Improved palatability: The denser texture of pellets can make them more appealing to animals.

What are the advantages of a flat die pelletizer (a type of medium capacity machine)?

- Cost-effective: Flat die machines are generally more affordable than other types of pellet mills.

- Simple design: They are easier to operate and maintain.

- Low energy consumption: They require less power to operate.

- Suitable for small-scale production: They are ideal for small to medium-sized farms and feed mills.

What types of feed can be pelletized in a medium capacity machine?

These machines can handle various feed ingredients, including:

- Grains like corn and wheat

- Soybean meal

- Grass powder

- Straw (broken)

Only logged in customers who have purchased this product may leave a review.

Related products

₦54,887,500.00

₦1,596,250.00

3.89

9 reviews for Medium Capacity Feed Pelletizer

There are no reviews yet.