PALM DIGESTER

₦890,000.00

20 people are viewing this product right now

🔥 4 items sold in last 3 hours

A palm digester is a specialized vessel used in the palm oil extraction process. It facilitates the breakdown of palm fruit bunches by applying heat and pressure, effectively separating the palm oil from the fruit’s pulp. This crucial step in palm oil production ensures efficient extraction of oil while maintaining quality standards. The digester plays a key role in the overall palm oil milling process, contributing to higher yields and optimal extraction efficiency.

Buy more save more!

Buy from 5 to ∞ items and get 5% OFF

on each productPALM DIGESTER

Picking the right digester of great is vital for your palm oil handling business. PALM DIGESTER guarantees high results, low creation costs, and high benefits. Our offered palm oil digester/presser is intended to assist our clients with limiting the expense and endeavors of delivering great palm oil.

Get in touch with us now!

PALM DIGESTER

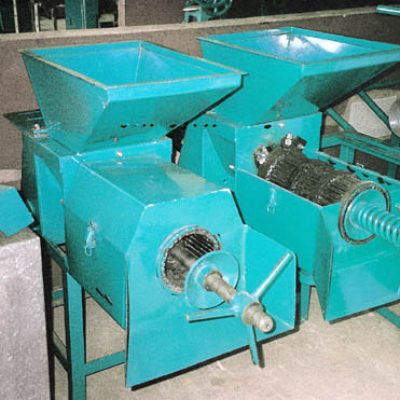

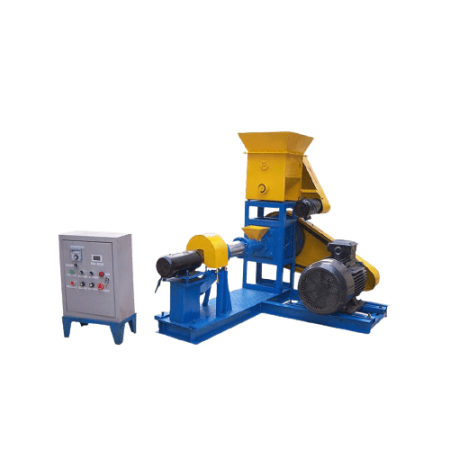

The palm oil digester machine is comprised of a warmed round and hollow compartment furnished with a focal turning bar and conveying some mixing or beating arms. It is utilized to pound sanitize palm organic products to natural product mash in palm oil creation. The palm oil extraction productivity is enormously worked on in the wake of the processing process.

PALM DIGESTER is utilized to deliver palm oil in the natural product by separating the oil-bearing cells. It is planned in light of the standard of rotational effect. The primary piece of the palm natural product digester is a turning pole with many mixing arms or digester blades. During the processing system, cleaned palm organic products will be squashed by these blending arms, with the infusion of hot steam.

Highlights/Benefits of the PALM DIGESTER

It tears open the external covering of the palm of organic product, which is known as the monocarp.

It slackens the monocarp from the nut.

It pounds the organic product into a squash and supplies hotness to the natural product to work with the squeezing system.

Processing further develops creation proficiency.

It additionally decreases the oil buildup in palm cake, and forestalls harm to the palm oil press machine.

It has programmed control.

Simple activity and upkeep

PALM OIL PRODUCTION PROCESS

The initial phase in the palm oil creation process is gathering palm natural products. Gathered packs are moved to plants where they are first cleaned and afterward sifted utilizing suitable hardware. Once isolated from the pack, the natural products go through a digester, to then be precisely squeezed to separate oil from the mash.

The mash of the full-grown natural product normally contains 56-70% of consumable oil. The parts are isolated out at this stage and squeezed freely to separate palm bit oil.

Raw petroleum is additionally refined through physical and synthetic cycles relying upon what the finished result ought to be. Degumming, fading, and freshening up are average refining exercises. In the wake of refining, the last advance of the palm oil creation cycle might be to fraction(separate) the oil into fluid and strong stages.

Frequently Asked Questions about Palm Digester:

What is a Palm Digester?

A palm digester is a heated, cylindrical tank equipped with a rotating central shaft and mixing arms. It’s used to mash and sanitize palm fruits during palm oil production, significantly improving oil extraction efficiency.

How does a Palm Digester work?

The digester breaks down the outer shell (monocarp) of the palm fruit, separates it from the nut, and mashes the fruit while introducing hot steam. This process softens the fruit, improves oil extraction, and reduces oil content in the remaining palm cake, protecting the palm oil press machine.

What are the benefits of using a Palm Digester?

- Breaks down the fruit’s outer shell, facilitating oil extraction.

- Separates the shell from the nut.

- Mashes the fruit and applies heat, preparing it for pressing.

- Increases overall oil extraction efficiency.

- Reduces oil buildup in palm cake, protecting the press.

- Offers programmed control for ease of operation.

- Provides simple operation and maintenance.

What is the Palm Oil Production Process?

- Harvesting: Palm fruits are collected from plantations.

- Cleaning and Sorting: The harvested bunches are transported to processing plants where they are cleaned and separated from non-fruit material.

- Digesting: Cleaned fruits go through the digester for further processing.

- Pressing: The digested mash is then pressed to extract the crude palm oil.

- Clarification and Refining: The crude oil undergoes physical and chemical processes to remove impurities and produce the final product.

- Fractionation (Optional): The final oil may be further separated into liquid and solid fractions.

Only logged in customers who have purchased this product may leave a review.

Related products

₦873,062.50

![PALM CRACKER 1 <blockquote> <div class="react-scroll-to-bottom--css-txuum-1n7m0yu"> <div class="flex flex-col text-sm pb-9"> <div class="w-full text-token-text-primary sm:AIPRM__conversation__response" data-testid="conversation-turn-8"> <div class="px-4 py-2 justify-center text-base md:gap-6 m-auto"> <div class="flex flex-1 text-base mx-auto gap-3 md:px-5 lg:px-1 xl:px-5 md:max-w-3xl lg:max-w-[40rem] xl:max-w-[48rem] group final-completion"> <div class="relative flex w-full flex-col agent-turn"> <div class="flex-col gap-1 md:gap-3"> <div class="flex flex-grow flex-col max-w-full"> <div class="min-h-[20px] text-message flex flex-col items-start gap-3 whitespace-pre-wrap break-words [.text-message+&]:mt-5 overflow-x-auto" data-message-author-role="assistant" data-message-id="c4cfaf2d-b878-42a8-8057-7de593486578"> <div class="markdown prose w-full break-words dark:prose-invert light"> A palm digester is a specialized vessel used in the palm oil extraction process. It facilitates the breakdown of palm fruit bunches by applying heat and pressure, effectively separating the palm oil from the fruit's pulp. This crucial step in palm oil production ensures efficient extraction of oil while maintaining quality standards. The digester plays a key role in the overall palm oil milling process, contributing to higher yields and optimal extraction efficiency. </div> </div> </div> <div class="mt-1 flex justify-start gap-3 empty:hidden"> <div class="text-gray-400 flex self-end lg:self-center justify-center lg:justify-start mt-0 -ml-1 h-7 visible"> <div class="flex items-center gap-1.5 text-xs"></div> <div class="flex"></div> </div> </div> </div> </div> </div> </div> </div> </div> </div> <div id="AIPRM__sidebar-icon" class="AIPRM__p-2 AIPRM__top-12 md:AIPRM__top-2 AIPRM__p-2 AIPRM__items-center AIPRM__transition-colors AIPRM__duration-200 AIPRM__cursor-pointer AIPRM__text-sm AIPRM__rounded-md AIPRM__border AIPRM__bg-white dark:AIPRM__bg-gray-900 AIPRM__border-black/10 dark:AIPRM__border-white/20 hover:AIPRM__bg-gray-50 dark:hover:AIPRM__bg-gray-850 AIPRM__cursor-pointer AIPRM__fixed AIPRM__right-4 AIPRM__z-30" title="Open AIPRM sidebar"></div></blockquote> PALM CRACKER PALM CRACKER](https://farmpays.com/wp-content/uploads/2022/03/cracker-600x600-1-100x100.jpg)

![PALM HARVESTER 2 <blockquote> <div class="react-scroll-to-bottom--css-txuum-1n7m0yu"> <div class="flex flex-col text-sm pb-9"> <div class="w-full text-token-text-primary sm:AIPRM__conversation__response" data-testid="conversation-turn-8"> <div class="px-4 py-2 justify-center text-base md:gap-6 m-auto"> <div class="flex flex-1 text-base mx-auto gap-3 md:px-5 lg:px-1 xl:px-5 md:max-w-3xl lg:max-w-[40rem] xl:max-w-[48rem] group final-completion"> <div class="relative flex w-full flex-col agent-turn"> <div class="flex-col gap-1 md:gap-3"> <div class="flex flex-grow flex-col max-w-full"> <div class="min-h-[20px] text-message flex flex-col items-start gap-3 whitespace-pre-wrap break-words [.text-message+&]:mt-5 overflow-x-auto" data-message-author-role="assistant" data-message-id="c4cfaf2d-b878-42a8-8057-7de593486578"> <div class="markdown prose w-full break-words dark:prose-invert light"> A palm digester is a specialized vessel used in the palm oil extraction process. It facilitates the breakdown of palm fruit bunches by applying heat and pressure, effectively separating the palm oil from the fruit's pulp. This crucial step in palm oil production ensures efficient extraction of oil while maintaining quality standards. The digester plays a key role in the overall palm oil milling process, contributing to higher yields and optimal extraction efficiency. </div> </div> </div> <div class="mt-1 flex justify-start gap-3 empty:hidden"> <div class="text-gray-400 flex self-end lg:self-center justify-center lg:justify-start mt-0 -ml-1 h-7 visible"> <div class="flex items-center gap-1.5 text-xs"></div> <div class="flex"></div> </div> </div> </div> </div> </div> </div> </div> </div> </div> <div id="AIPRM__sidebar-icon" class="AIPRM__p-2 AIPRM__top-12 md:AIPRM__top-2 AIPRM__p-2 AIPRM__items-center AIPRM__transition-colors AIPRM__duration-200 AIPRM__cursor-pointer AIPRM__text-sm AIPRM__rounded-md AIPRM__border AIPRM__bg-white dark:AIPRM__bg-gray-900 AIPRM__border-black/10 dark:AIPRM__border-white/20 hover:AIPRM__bg-gray-50 dark:hover:AIPRM__bg-gray-850 AIPRM__cursor-pointer AIPRM__fixed AIPRM__right-4 AIPRM__z-30" title="Open AIPRM sidebar"></div></blockquote> PALM HARVESTER PALM HARVESTER](https://farmpays.com/wp-content/uploads/2022/03/download-70-100x100.jpg)

₦581,250.00

Reviews

There are no reviews yet.